In the ever-evolving world of electronics, terms like PCBA and SMD components are commonly mentioned. For professionals and enthusiasts alike, understanding these concepts is essential to grasp how modern electronic devices are manufactured. This article will explore the meaning of PCBA, the importance of SMD components, and how the two work together to create cutting-edge electronics.

What is the PCBA Meaning?

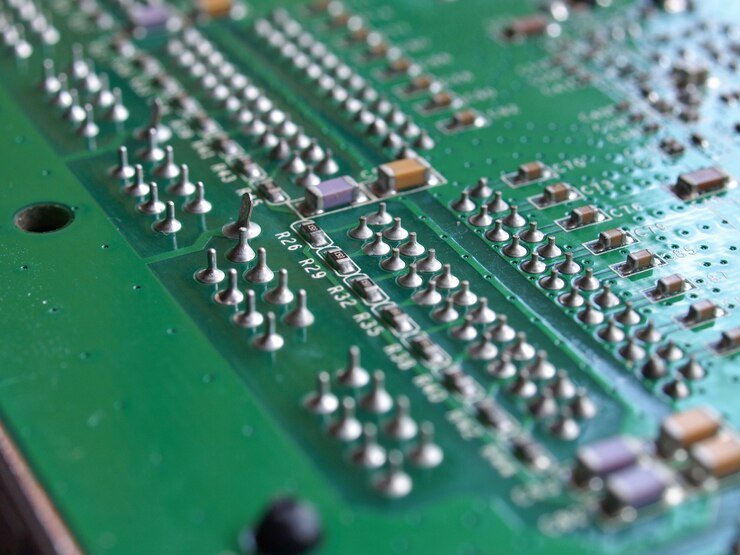

PCBA stands for Printed Circuit Board Assembly, which refers to the process of assembling components onto a printed circuit board (PCB). This process transforms a blank PCB into a fully functional electronic circuit that powers devices such as smartphones, computers, and IoT gadgets.

Key Steps in PCBA Process:

- Solder Paste Application: A thin layer of solder paste is applied to the PCB where components will be placed.

- Component Placement: Components, including SMD components, are placed on the board using high-precision machines.

- Reflow Soldering: The board is heated in a reflow oven, melting the solder paste to secure the components.

- Inspection and Testing: Automated Optical Inspection (AOI) and functional testing ensure the assembly works as intended.

The term PCBA is often confused with PCB, but the two are different. While a PCB is just the bare circuit board, a PCBA includes all the components mounted on it, ready for operation.

What are SMD Components?

SMD stands for Surface-Mount Device. These are electronic components that are mounted directly onto the surface of a PCB, rather than being inserted into holes as in traditional through-hole technology. SMD components are compact, lightweight, and highly efficient, making them a cornerstone of modern electronics.

Common Types of SMD Components:

- Resistors: Control the flow of electrical current.

- Capacitors: Store and release electrical energy.

- Diodes: Allow current to flow in one direction.

- ICs (Integrated Circuits): Contain complex circuitry in a small package.

- Transistors: Amplify or switch electronic signals.

These components are widely used in PCBA due to their small size and high performance, allowing for compact and lightweight device designs.

The Role of SMD Components in PCBA

SMD components play a critical role in the PCBA process, driving advancements in technology and enabling innovative designs. Here’s how they impact PCBA manufacturing:

- Space Efficiency

SMD components are significantly smaller than their through-hole counterparts. This allows manufacturers to fit more components onto a single PCB, leading to compact designs for devices like smartphones and wearables.

- High-Speed Assembly

Modern PCBA processes rely on automated machines to place SMD components rapidly and accurately. This reduces production time and improves efficiency, meeting the demands of high-volume manufacturing.

- Enhanced Performance

SMD components provide better electrical performance due to shorter lead lengths, which minimize resistance and inductance. This is especially critical in high-frequency circuits used in telecommunications and computing.

- Cost-Effectiveness

While initial setup costs for SMD manufacturing may be higher, the overall production cost is reduced due to faster assembly speeds, smaller component sizes, and lower material usage.

- Improved Reliability

SMD components are soldered directly to the PCB surface, providing better mechanical stability. This makes the final assembly more resistant to vibrations and shocks, a key factor for devices used in harsh environments.

How PCBA and SMD Components Shape Modern Electronics

The combination of PCBA manufacturing and SMD components has revolutionized the electronics industry. Here’s how this synergy drives innovation:

- Miniaturization: The use of SMD components in PCBA has enabled the creation of smaller, lighter, and more portable devices.

- High-Performance Devices: By leveraging the advanced capabilities of SMD components, PCBA manufacturers deliver devices with superior performance in areas like speed, energy efficiency, and reliability.

- Scalability: Automated PCBA processes, designed for SMD components, allow manufacturers to produce large quantities of high-quality electronics efficiently.

Conclusion

In summary, PCBA (Printed Circuit Board Assembly) is the backbone of modern electronics, and SMD components are the driving force behind its success. Together, they enable manufacturers to create compact, reliable, and high-performance devices that power everything from consumer gadgets to industrial equipment.

Understanding the meaning of PCBA and the role of SMD components is crucial for anyone involved in the electronics industry. As technology continues to evolve, the synergy between PCBA and SMD components will undoubtedly shape the future of electronics, delivering innovations that redefine our digital world.